New Inspection Module : Improved Traceability & User Experience

We have Implemented a New Inspection Module within our Final Inspection Department!

We are always reviewing our processes, looking to develop and improve our service and products into our customers. The most recent Continuous Improvement Project (CIP) to complete, is the introduction of our new Inspection Module within our system.

This area was identified and proposed for review by submitting onto our Continuous Improvement Board. After successful review with the team, a new Project Team was formed and work began on Defining, Measuring & Analysing the current process. It was clear the current process was heavy on the manual set up and input.

Our Project Team discussed with various Accounts to understand their needs & wants and subsequently identified a new Inspection Module within our current MRP system. This new module could be utilised and adapted to suit our customers requirements. After working cross-departmentally the team have successfully implemented this new module, this brings the following benefits to ourselves and our customers:

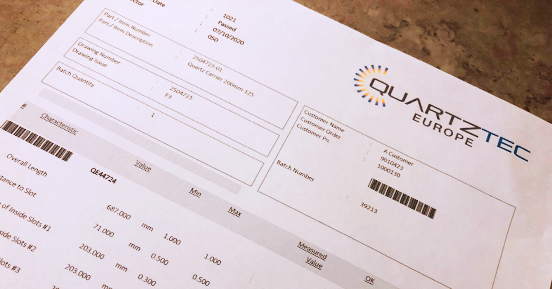

- Fully Linked to our Customer’s Order

- Barcodes on the Inspection Reports

- Standardised Measurement Points from Part to Part

- Fully Traceable at a Click of a Button!

- Intuitive and Interactive Interface

- Sleek, Professional Report

- Improved User Experience

All of our products undergo an Inspection prior to being shipped to our customers, to ensure full compliance to specifications. Now with our new Inspection Module being fully implemented we can supply – detailed, fully traceable and professional looking – reports with your products!

We thank the CIP team who managed this project from start to finish and successfully installed an improved process within the business!

Thank you, team!

For other News updates, follow us at Quartztec – LinkedIn and see our Quartztec News Page